3800mm Three Wire Foudrinier Paper Machine for Kraft/Liner paper

3800mm Three Wire Foudrinier Paper Machine for Kraft/Liner paper

Paper Machine Parameter:

Output: Kraft paper, corrugated paper

GSM arrange: 100-200g/m2

Trimmed width: 3800

Working speed: 150-180m/min

capacity: 100-120t/d

Rail space: 4700mm

Drive form: AC frequency conversion, section drive

Right-had machine

Arrangement of paper machine

3 Pcs Head box—Three layer fourdrinier wire(7m face wire, 15m medial wire, 21m bottom wire)—suction press(φ900/φ850)—jumbo pressφ1350/φ1350—jumbo pressφ1350/φ1350—20 Pcs dryer cylinder(φ1500)—size press(φ800/φ800)—10Pcs dryer cylinder(φ1500)—glossy calender(-φ1000/φ800)—horizontal pope reel—framework rewinder

Customer:Taiyuan Hongxin Paper Co.Ltd

Location:Taiyuan City,Shanxi Province,China

Wire section: 1.Remove water from the pulp. 2.Form the sheet as it begins its transformation to paper.

Press Section: The task of the press section of PAPER MACHINE is to continue to remove water from the pulp fibers and to smooth the surface characteristics of the felt and wire sides ( top and bottom sides ) of the paper web running the length of the machine. Various types of press section can be made based on the requirement.

Dryer Section: 1.Removal of water from the sheet.2.Achieve final desired MD & CD sheet moisture profiles while minimizing energy requirements.

Size Press: The Size Press is used for applying starches, pigments, or chemicals to the surface of the product. The chemicals applied can be used to strengthen the product or to improve the printing quality of the product or even to improve the softness of the product.

Features:

Improve strength, surface smoothness in writing/printing/Media/Kraft/board

Add pigments to the surface of the web.

Better printability in printing paper/Kraft/Board

Improves bursting strength in Kraft papers

Calender:The primary purposes of the calender are can be summarized below.

Increase the quality of the final product.

Make the paper surface extra smooth and glossy

Gives it a more uniform thickness to the final product.

Pope Rell: The pope reel section serves as the final part of the paper making machine process.The pope reel is used for winding paper web into a paper roll.The pope reel has to keep pace with machine production without damaging the final product. The purpose of the reel can be summarized as follows:

Winding a continuous web of paper into “Jumbos/logs” that can be processed in subsequent operations.

Rewinder: Paper doesn’t generally sold by the jumbo, thus it must be scaled down. The slitter rewinder is used to process these jumbos made from paper making machine into manageable and sellable products, the width and tightness of rewinding meets the requirements of finished sheet rolls. In the process of rewinding, it can also remove the bad-quality paper sheets, adhesive end breakage.

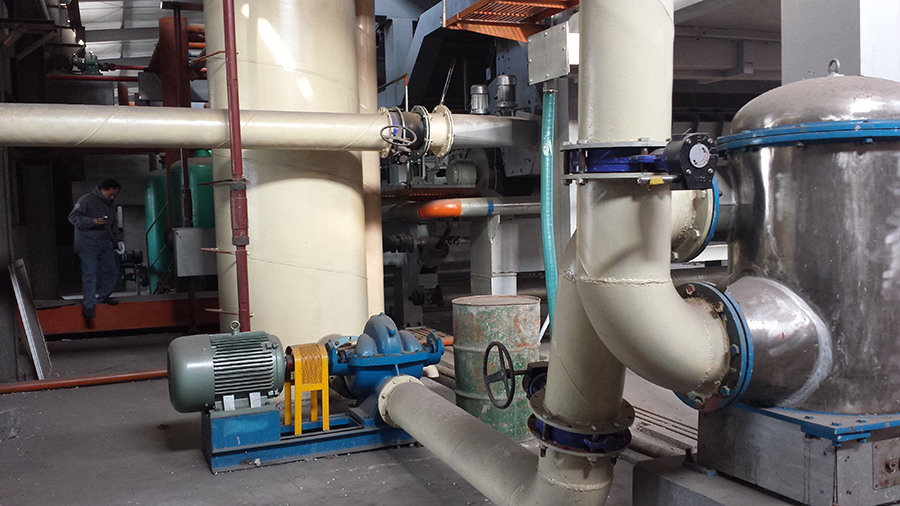

Vacuum System: Vacuum pump belongs to the paper making section, used for vacuum dewatering.

Approach flow system:

China Leading PAPER MACHINE manufacturer,stock preparation equipments,cylinder mould paper machine,fourdrinier paper machine,paper making machine,toilet paper machine, toilet tissue paper making machine,corrugated paper machine, A4 copy paper machine,Kraft paper machine, writing paper machine,printing paper machine,etc.